Originally Posted by

Michael_D

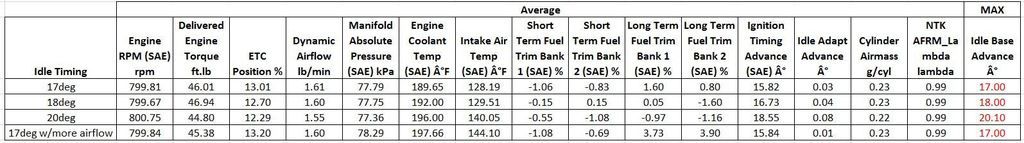

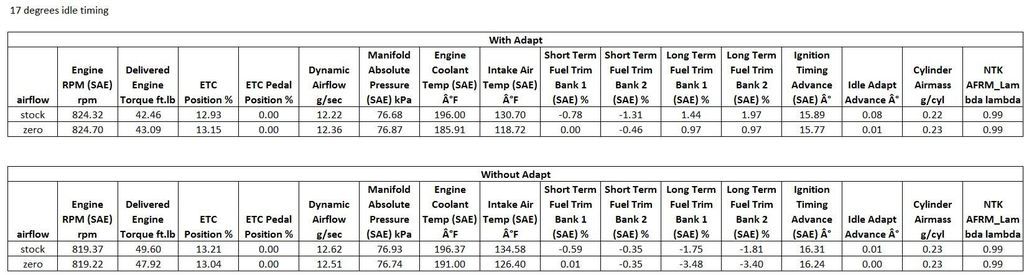

A couple weeks back, I was experimenting with min air for low rpm highway cruising. Just to see if it had an effect...(it does btw). Whilst doing this, my min air was double what it needs to be. My final idle spark was 12 deg, with very slight dips below 12, and swings up to 18. My idle spark table value was 18. The average (histo 11) would dial in to <.1, even though adaptive spark was grossly biased towards the negative.

After I was done futzing around with this, I moved my air back to where it should be. My idle spark is back to 18, and adaptive spark moves it +/- from 18 nicely. I suspect if you were to halve min air, you would see the opposite effect, and idle spark would max out at whatever base is, + adaptive. It would then bounce around a bit, but not much.

So, based on my observations, I would always start out with the OE min air table (assuming you can actually start the engine after a cam swap). I would then set idle to about 1000, and then find where your main idle spark should be. You can get all scientific if you want, but I don't see a need when you can watch your MAP. Keep raising spark until you do not see an increase in vacuum. Then lower it a few degrees. Refer to your adaptive spark table, and lower it a corresponding amount, to give adaptive spark room to work (add/pull spark). At this point, you can start fussing with min air. Raise it a couple g/sec, log, watch your spark. Keep raising and watching. When you find final running idle spark start to lower from too much air, you know the upper boundary. Then work your way back down. When you know your close, use the adaptive spark histo to dial it in. After done, if the throttle still hangs, or dips too low - move to the follower torque table.

As far as the min idle air cells above 1200, I think they need values. If you are out rallying around, fourth gear, 4500 rpm, then pop into N and coast ? you don?t want the engine to die. If you don?t have a value in the cell, what?s to keep the throttle blade open? I dunno, maybe it won?t, but why risk it? Some super smart GM engineer thought it was important enough to put some work into the table values, so I?m going to follow his/her lead.

So what do you move them to? Not real sure what the ?correct? amount is, but I?ll describe what I did, and I think it?s working??..

After I got my 600, 800, 1000, 1200 idle values dialed in, I dropped the OE table values back into the cells above 1200, so I had the OE values to work with.

I then used Excel to figure out percentage based differences in the entire OE table. I found the % increase between the idle 1200 cell, and highest OE value in this row. I then multiplied my ?modified? value by the same amount in this cell and used the HPT interpolate function between this cell and the 1200 cell. I then carried the 1200 value to the far right. At this point my idle row was done. I once again referred to the OE table, idle row. I then compared this row to the remaining rows, using Excel. Found the percent difference between the idle row, and all others. Then I just took my ?modified? idle row, and multiplied it by the % difference I found with the remaining OE table row values. Then it?s just a copy/paste into the table. For example (not using actual values): 1800 rpm value / idle row, verse 1800 rpm value 4th gear row = +4%. Clear as mud?

Reply With Quote

Reply With Quote