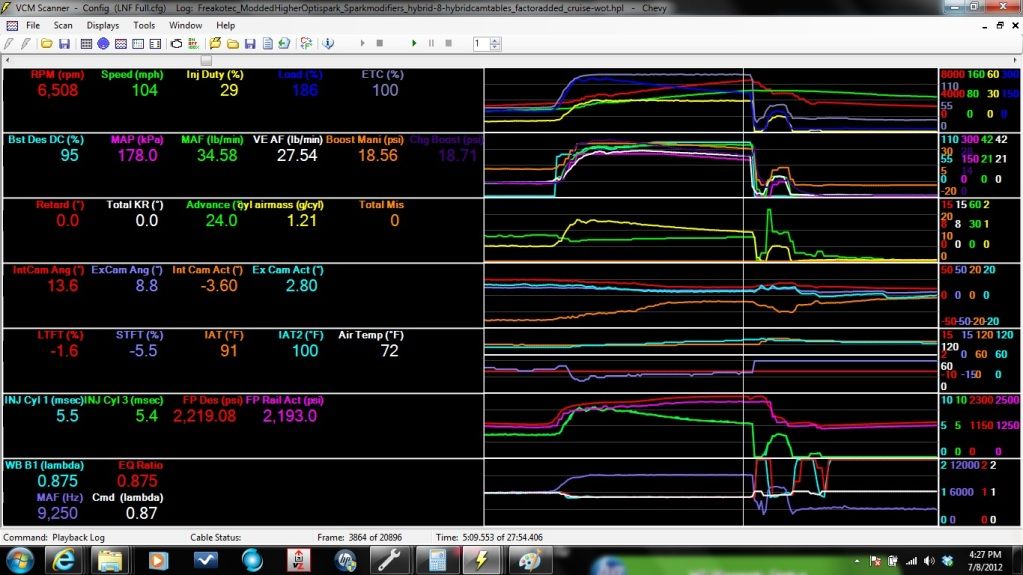

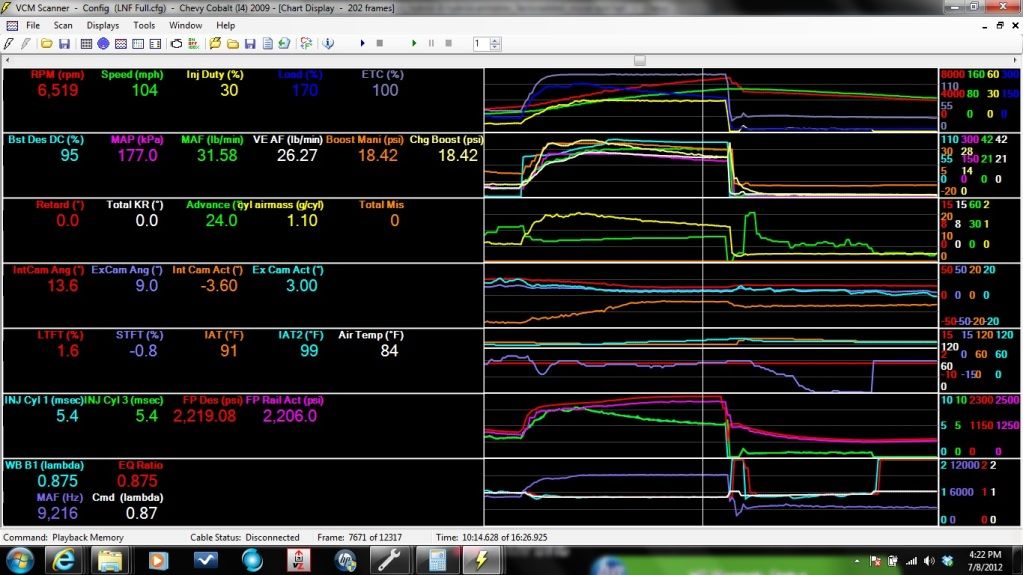

So I'm still getting some mixed results from these tables ESPECIALLY at WOT. I tried seeing what effects increasing the areas mainly from 3k-redline at wot would have without making too many other changes to other tables that could skew results, such as DAL's and cam. So far I'm really not sure what to make of it. It seems as though if I go just a couple "clicks" too high in the high load areas it seems as though I'm losing a bunch of airflow, airload, and airmass (obviously I'm sure they're all related). It's also noticed in my injector pulse widths (however not by a huge difference though). At 6500rpm in the log where I have more airmass I'm seeing a 5.5m/s pw, and in the log with less airmass at the same rpm I'm seeing a 5.4m/s pw. Granted I know it's not much but I'm just looking at all the areas that are different.

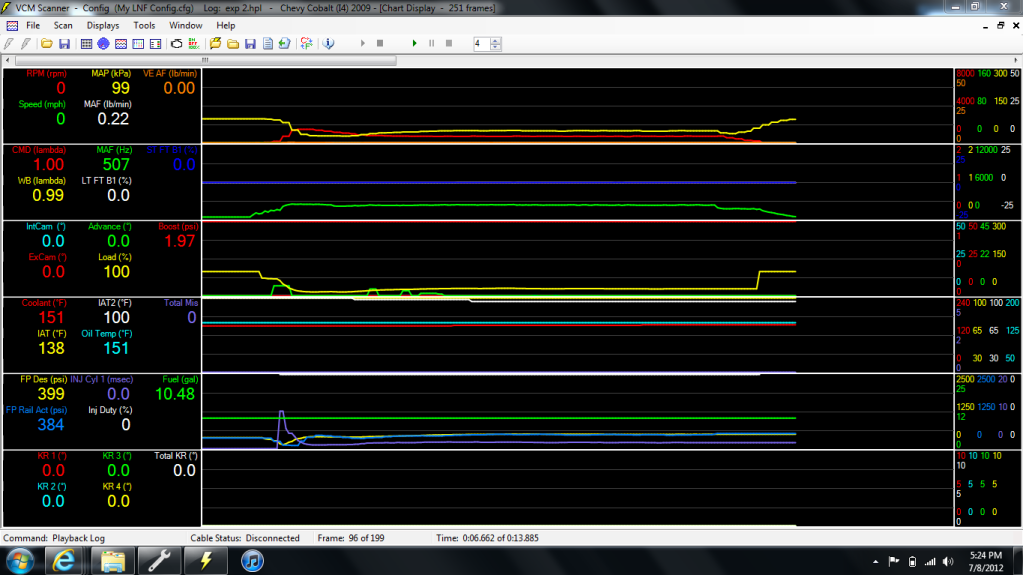

So anyways, here are a couple of screen shots to show what I'm talking about. First is of where I raise the wot areas relatively substantially, and saw a decent gain in flow.

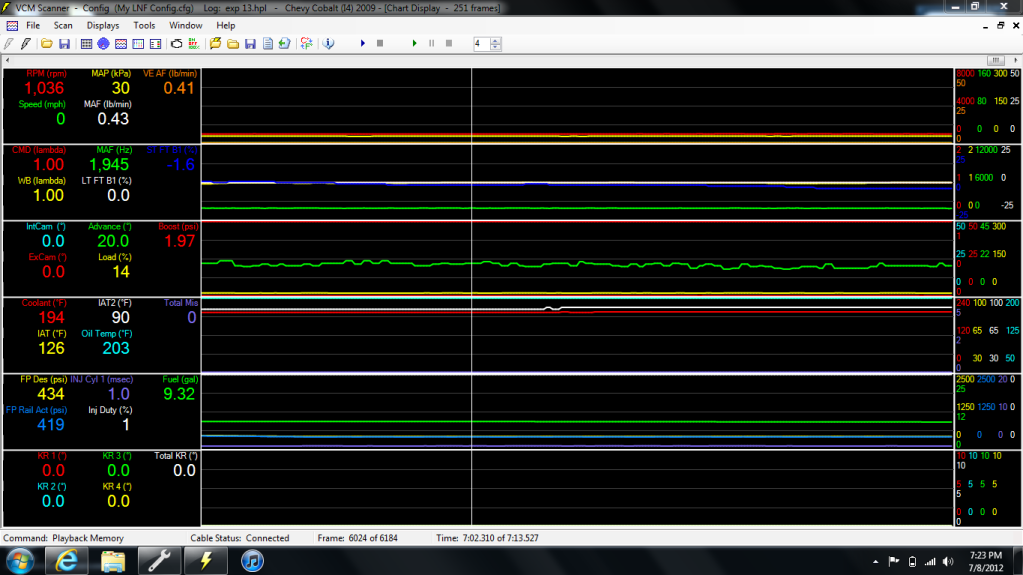

This next one is basically the same tune file, aside from slightly higher values in the WOT areas. Notice the relatively drastic drop in airflow between the 2 logs?

One last thing I noticed while making these changes is that it seems to throw the trims off a decent amount. I'm not sure if it's just my evap purge solonoid throwing things off on me or not, but again, it's just something I noticed in the logs.

I'm curious to see what results anyone else who is tweaking these tables has come up with just as something to compare my findings to. I don't know, maybe I'm just missing something here. Let me know what you guys think. Thanks..

[/IMG]

[/IMG] [/IMG]

[/IMG]