Precisely. The basic workflow for the ECU is:

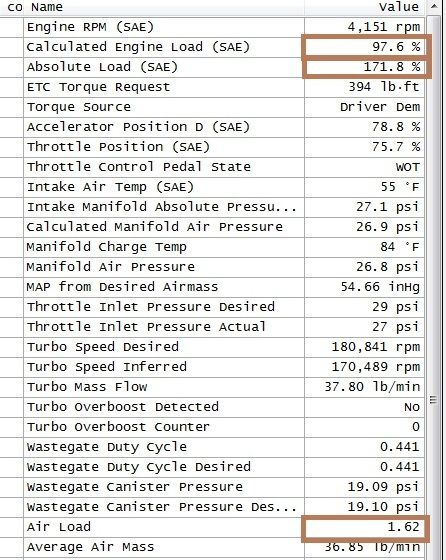

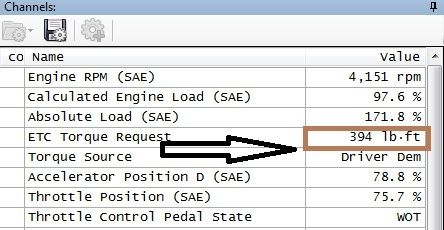

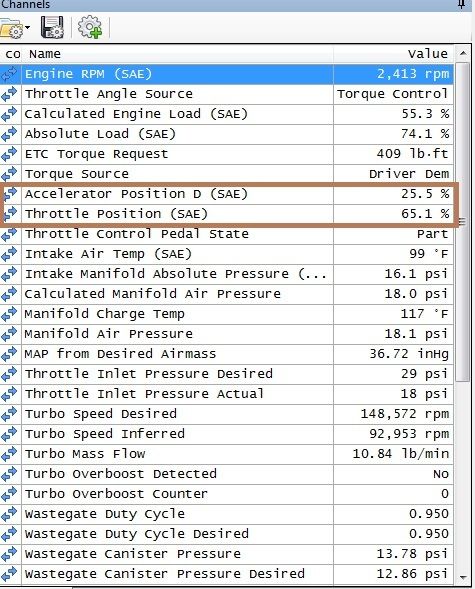

Torque Desired -> Load Desired -> Airflow Desired -> MAP Desired -> TIP Desired -> Turbine Conditions needed (Mass fraction etc) -> Final WG Request.

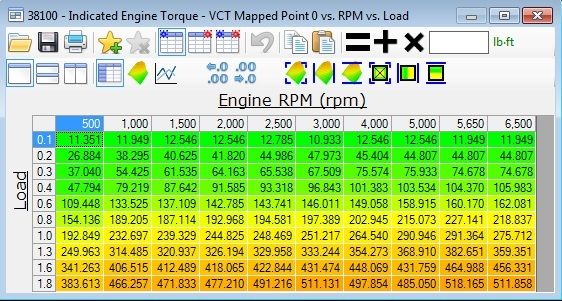

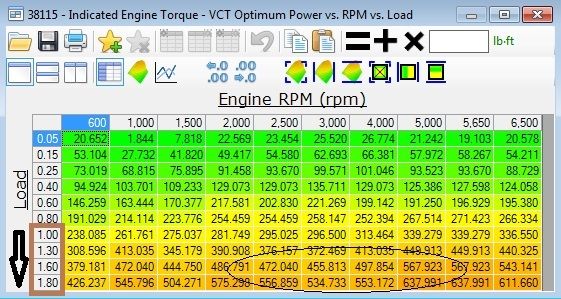

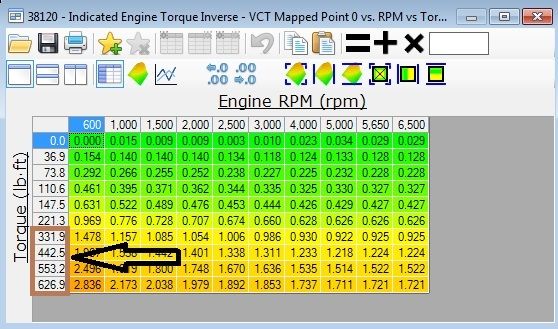

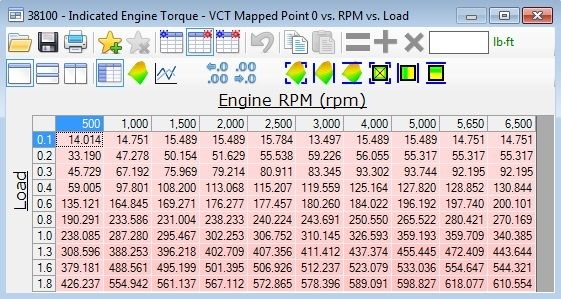

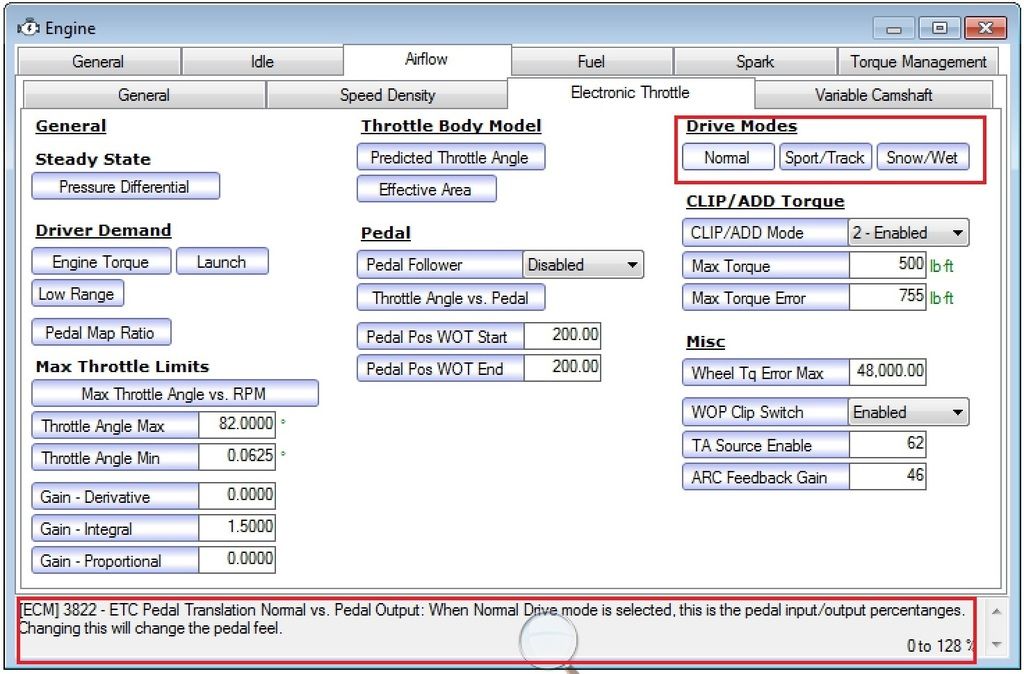

You need to work your way through each stage. Torque Desired to Load Desired through the Torque to Load tables, Load to Airflow is a basic calculation, Airflow to MAP is through the VE equations, MAP to TIP is a few tables which might not be available on your strategy (essentially just to have delta pressure over the throttle for better transient performance), turbine conditions is fancy math you dont really have control over, and you obviously have the wastegate maps.

The goal then is to get TIP Desired up by getting your Torque Desired/Load Desired up, and then to tune your wastegate system until you can get TIP Actual to match TIP Desired in as many conditions as you can. If TIP Actual > TIP Desired (and thereby MAP Actual > MAP Desired), the ECU closes the throttle to control the airflow delivered. You're basically going the right direction with what you want to do.

Reply With Quote

Reply With Quote