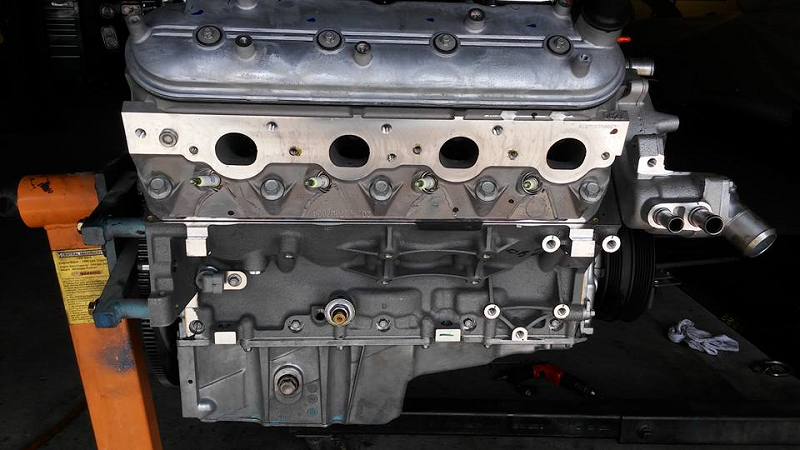

We have done a couple of these ls3 480 swaps. The last was on a 2007 corvette. This one is on an old Camaro. One thing that I like to do when doing these swaps is I like to keep the knock sensors correct to the controller. I know there are wiring harness adapters to allow for using the new sensors with the older controller, but I believe it is more correct to remove the newer style knock sensors from the sides of the new motor..

And drill and tap the block to recieve the gen 3 knock sensors that were removed from the ls1 valley..

The LS3 has different connectors on the injectors and map sensor, we moved the knock sensors from the valley to the sides of the block, and we are deleting all the secondary air stuff so there are some changes that need to be made to the harness..

Here the motor is fully dressed with new ARH longtubes and ready to go back into the Camaro..

And of course..

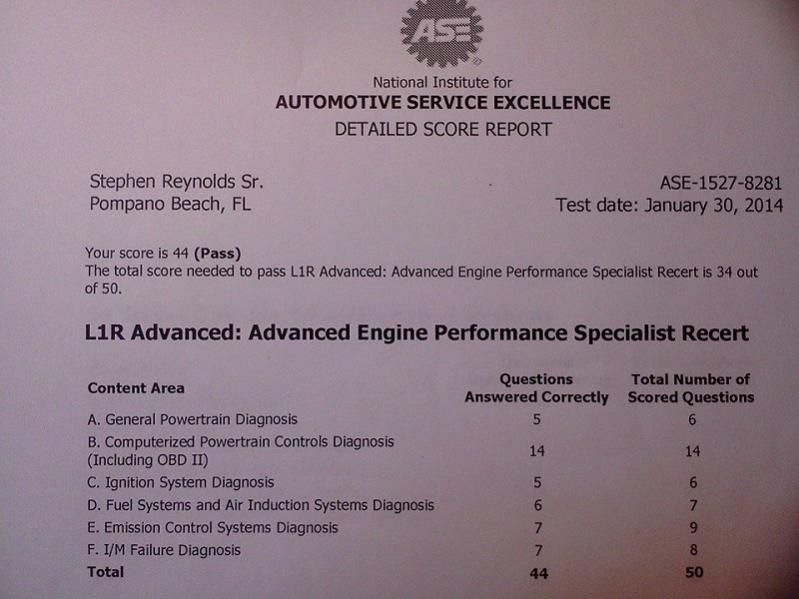

Better than any watermark. And here is where we stopped for the holiday weekend..

I should have this completely wrapped up by lunchtime or a little after on Tuesday and hopefully by the time I leave work on Wednesday I will have that .hpt file to post up here. I will save a log of its final pull on the dyno.

Reply With Quote

Reply With Quote