I'm having an issue where the engine won?t accelerate past ∼3000 RPM under part throttle or WOT acceleration, feels and sounds like hitting a fuel cut rev limiter.

In scan data I'm seeing differences bank to bank with injector pulsewidth and O2 narrowbands: B1 INJ PW goes as much as 4msec higher than B2 and B1 O2 oscillates rapidly while I'm hitting this rev limit. My wideband is in B1 and confirms B1 is leaning out slightly.

I've swapped injectors, coils, plug wires, plugs and NB02s side to side and issue still persists on B1.

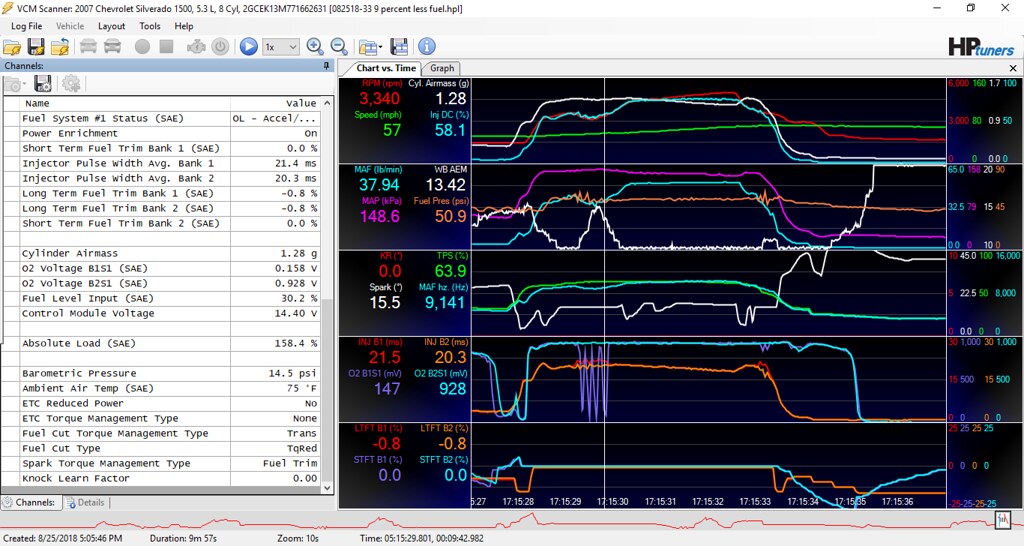

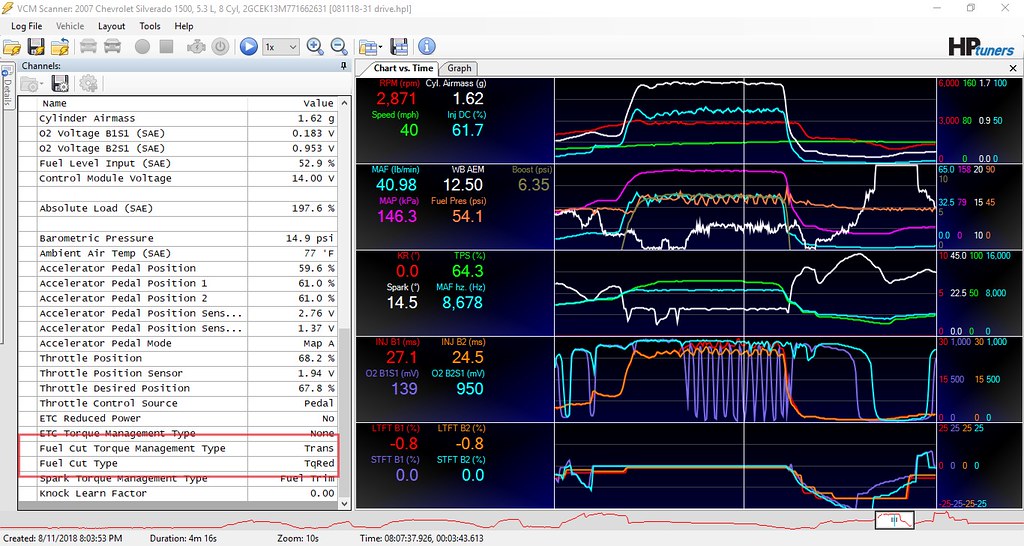

A few observations I've made from my recent log:

- Issue occurs ⪆ 60% TPS

- Cyl. Airmass seems high at ≥1.5-1.8 g

- Inj. DC chart data is jagged, fluctuating ∼5%

- Fuel pressure is also jagged, fluctuating ∼10% (this is the most notable piece of scan data that makes me point towards a fuel delivery problem)

- Bank 2 O2 reports rich as expected ∼945mV

- Bank 1 O2 oscillates rapidly ∼61-888mV

- Inj. PW seems high at ∼25-29msec, in past logs without this problem I saw around 20msec or less for 5,000 RPM WOT pulls

- Inj. PW B1 goes higher than B2 during this issue, for example B1 28.0 vs B2 24.6

I cannot understand why this problem manifests on B1 only (fuel system is returnless and enters on the B1 rail so this may have a factor).

I'm leaning more towards a mechanical issue but in my scan log where I have the problem (time stamp ∼3:40 and 3.55) the PIDs Fuel Cut Torque Management Type shows Trans and Fuel Cut Type shows TqRed, so I'm unsure what influence these two parameters have on vehicle fueling; could one or the other command a fuel cut on one bank only, but if so I assume this would cut or modify the Inj PW signal (maybe the VCM scanner doesn't have the resolution to record this and I'd only see it on a scope?).

A couple closing thoughts, it's a stock fuel pump on a Silverado 5.3 with a TVS1900 so I expect to hit the limits of this pump but I assumed the data would show this across both banks, not specifically on one.

A few of the valvesprings on B1 have pressures that are ∼20lbs less than what were advertised new so I'm planning to shim those springs just to rule out a valvetrain stability issue.

081118-31 drive.hplNew injector scaling.hpt

Reply With Quote

Reply With Quote