*SOLVED* See post #29 for full details:

http://www.hptuners.com/forum/showpo...1&postcount=29

Hello

I've been a lurker here for a little while but haven't posted a lot. I've been trying to absorb as much as I can. However, I've been tinkering with this problem for a few months now and I thought I'd throw it at the pros to see what they think of it.

I'll ask my questions up front just so they don't get lost in the rest of the post.

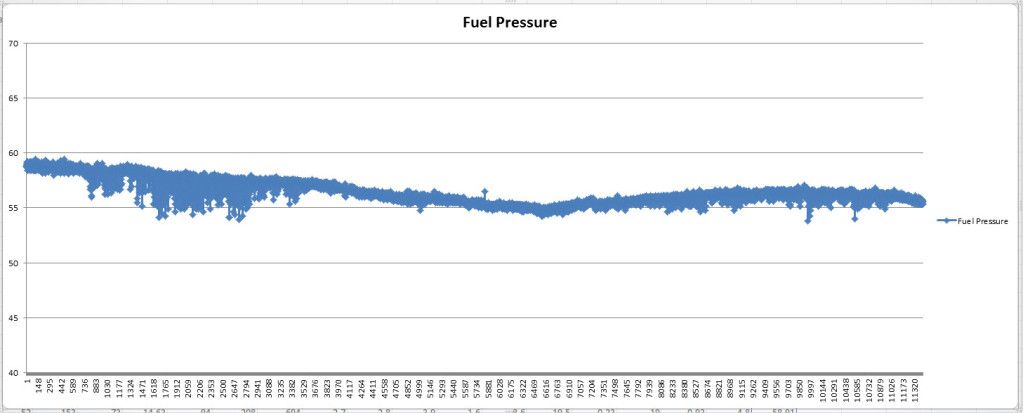

To anyone with experience in logging fuel pressure and tuning Gen3 GM engines. Will a 4psi swing affect open loop tuning / locked fuel trims? I'm thinking it will because I haven't been able to nail down my MAF tune, but I'm afraid I may be chasing my tail here.

Can anyone who has logged fuel pressure post their logs here? I'm specifically looking for GM applications in the 58psi range. Stock or Aftermarket FPR is ok. I'm just looking to see what a normal pressure range looks like on a return style system

Ok, so here's the meat. This is what I've got:

Build thread with full details = http://www.norotors.com/index.php?topic=70.0

Chassis = 1993 Mazda RX7

Engine:

Ls1 aluminum block built for 10.4:1 compression with only 4k miles on it as built.

Complete assembly is balanced

Forged flat top 3.90" Mahle pistons

Forged Eagle rods

Forged Eagle stroker crank with 4" stroke designed to displace 383CI.

Patriot LQ9 heads with 72cc chambers 2.055"/1.60" valves with harland sharp 1.7 roller rockers.

Comp pushrods and lifters.

Gm performance oil Pump and chain

Arp rod and main bolts

Trick flow head gaskets

Patriot custom cam .585"/.585" lift, 226/226 duration and 112 lsa

0 miles on the Water pump, Ac Compressor and both tensioners

Stock coils

MSD wires

LS6 Intake + PCV conversion

My original fuel system layout was as follows

-8AN Pickup from aftermarket sump -> -8AN 100um Summit Racing Fuel Filter -> Bosch 044 In line filter -> -8AN 10um Summit Racing fuel filter -> Aeromotive 13101 FPR

Splits to -> -6AN to Stock LS1 Fuel rail -> SVO #42 Greentop injectors

-> -6AN return line to 2nd port on the aftermarket sump

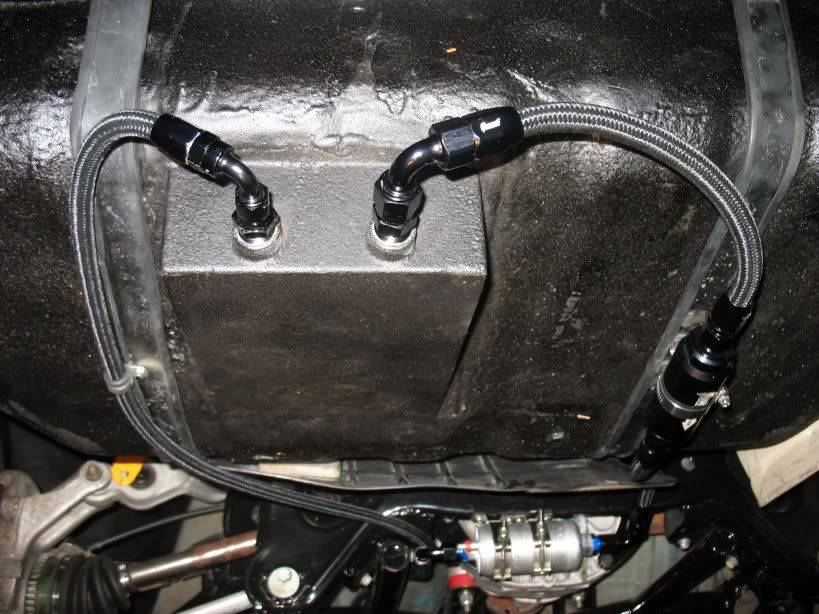

Here’s what my original return layout looked like:

Yes, that’s me returning fuel directly to the sump…. I finally realized that my returned fuel was probably aerated and was probably being picked up hot and bubbly in the sump causing cavitation at the pump. To fix this problem I capped the 2nd sump OUTLET and re-routed the return hose to the stock fuel pump location after modifying the inlet / outlet to –AN spec.

Unfortunately it didn’t solve my pressure problems, but I’m thinking it was a good idea anyway.

Fuel system layout as it is now:

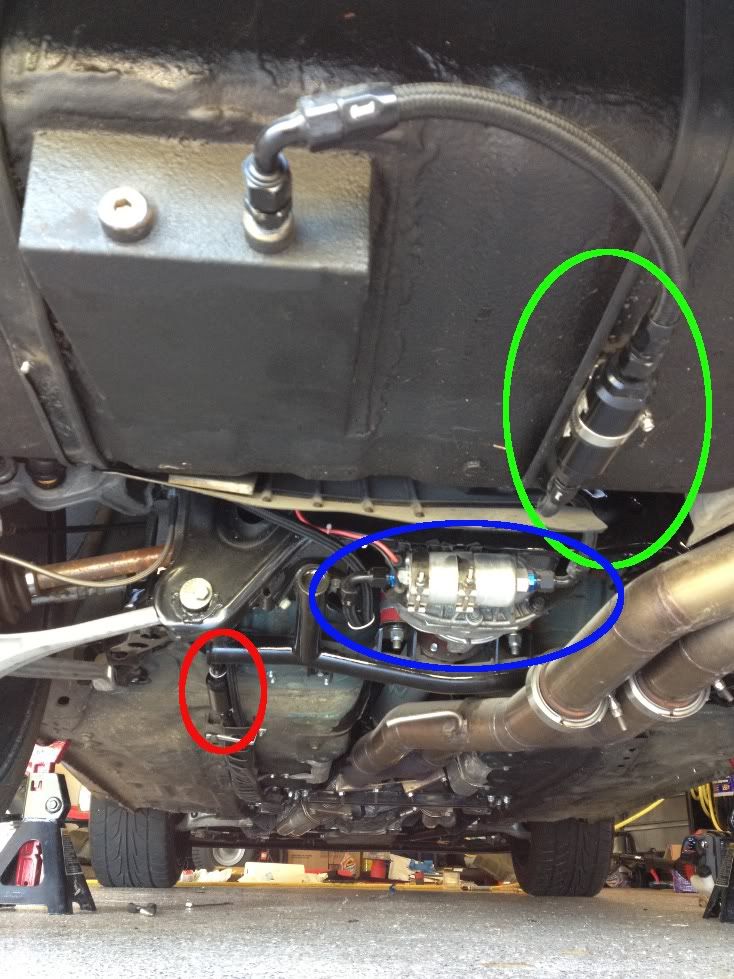

Green circle is the 100um pre-pump filter, the Blue circle is a Bosch 044, and the Red circle is the 10um post-pump filter.

And here’s an old picture of how I’ve got my regulator setup:

Fuel from the pump comes in from the -8AN inlet facing the rear of the car, fuel goes to the fuel rail out of the -6AN outlet facing the front of the car, and the return goes to the tank out of the -6AN outlet facing the bottom of the car. The only thing that’s changed is the post pump filter in the picture has been relocated.

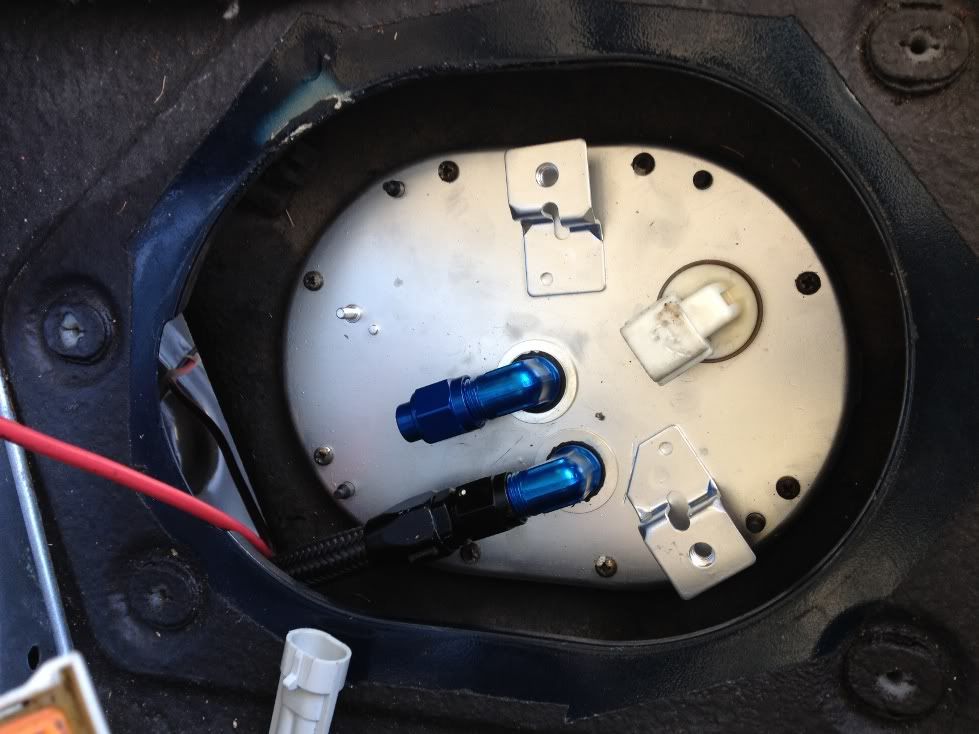

Here’s how I am reading pressure from the fuel rail:

Here are some links to some of the bigger parts in my system:

FPR:

http://www.summitracing.com/parts/AEI-13101/

100um filter:

http://www.summitracing.com/parts/SUM-230118-B/

10um filter:

http://www.summitracing.com/parts/SUM-230116-B/

Mechanical fuel pressure gauge:

http://www.summitracing.com/parts/SUM-800199/

Fuel pressure gauge and sender:

http://www.speedhut.com/custom_gauge...number-474.htm

Here's what I'm dealing with:

Here's the CFG and HPL from the run that graph came from:

http://www.halfspec.com/downloads/RX...2Work2Home.hpl

http://www.halfspec.com/downloads/RX...MWB_121812.cfg

Please ignore the WB and LAMBDA_err traces as they weren't setup correctly for this run. Also, this tune is very rough as I'm still in the early stages of tuning.

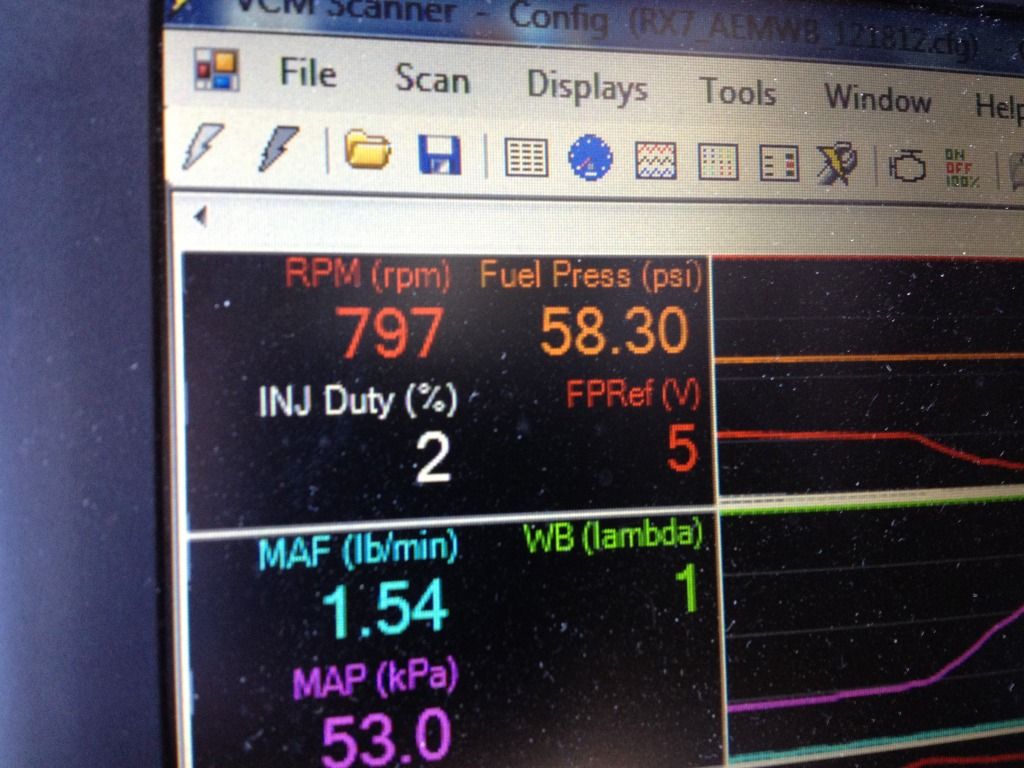

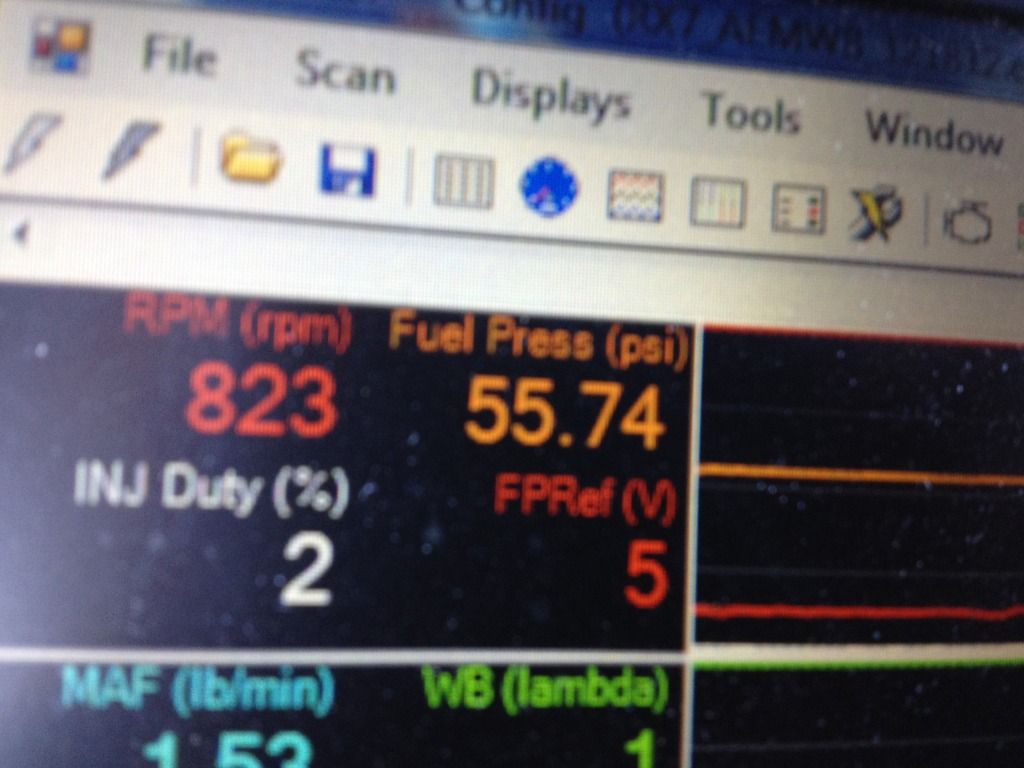

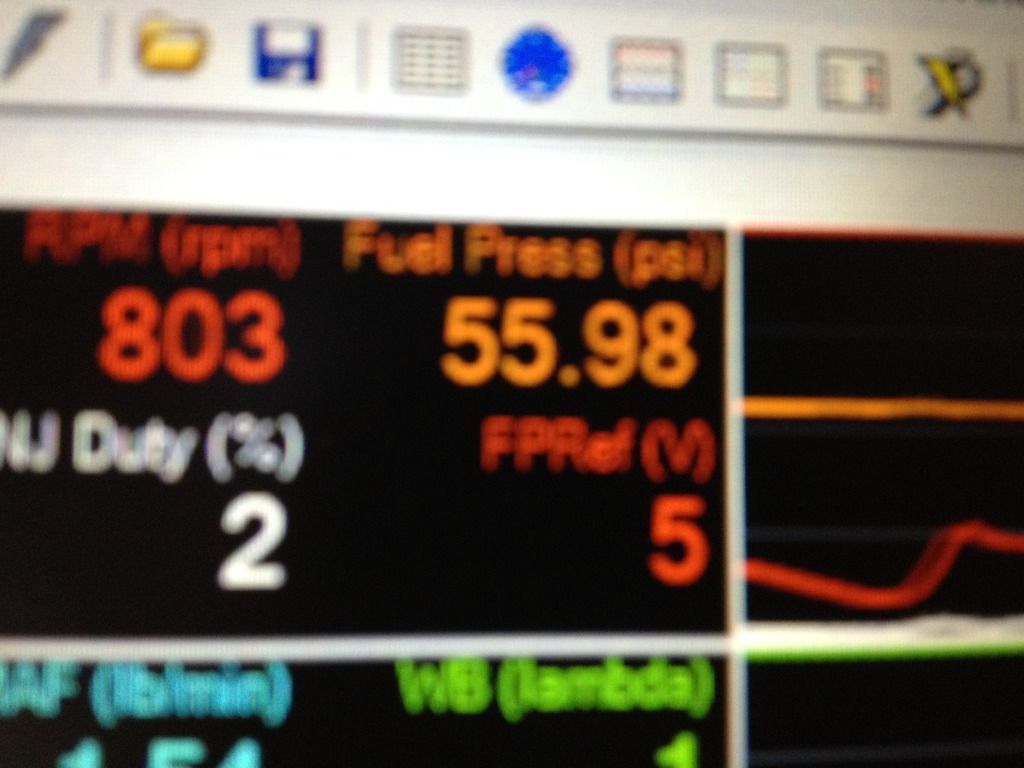

During that run I also made sure my readings were correct by comparing the logged values to the in-bay mechanical gauge reading from the same pickup. I snapped the pics at the beginning, middle, and end of the trip:

Sorry for the blurry pics. The engine vibration made it impossible for my "auto focus" camera to work.

What I've tried so far:

1. Cleaned out 100um pre-pump fuel filter and 10um post-pump fuel filter (they weren’t really dirty).

2. Moved pump’s ground

3. Moved post-pump fuel filter closer to pump. Moved from engine bay to under the car. This was more about a hood clearance issue, but I figured it was worth mentioning.

4. Disassembled my FPR. I just took off the top to inspect the set screw and diaphragm. Everything looked fine

5. Rerouted fuel return to the top of the tank to the stock fuel pump hanger lid (converted to 90 degree -6AN).

6. Rebuilt -6AN fuel return hose for #5.

7. Installed mechanical gauge to verify digital sender’s output (it did verify).

8. Bypassed the Fuel Pump's relay and ran it straight from the battery

with 10AWG wire.

9. Logged the speedhut FP sensor's 5v reference (it is fine and solid at 5v)

10. Logged the voltage across the fuel pump

11. Logged the current through the fuel pump using a shunt resistor.

12. Swapped out the Bosch 044 fuel pump for another Bosch 044 fuel pump.

13. Replaced the flared (Doh!) FPR fittings for ORB fittings

14. Swapped out the AEI-13101 FPR for another AEI-13101 FPR.

15. Disconnected the speedhut FP gauge from its sensor and powered + grounded the sensor independently with a regulated 5v circuit.

I am happy to post any data from the 15 things I've already tried if requested.

Any help is GREATLY appreciated as I've been scratching my head over this issue for months now.

Lane

Reply With Quote

Reply With Quote