After throwing the crank sensor code.

I

1 BOUGHT A NEW SENSOR\

2.BOUGHT A NEW PIGTAIL

3. CHECK VOLTAGE IN THE WIRING FROM THE PIN.

all check out good.

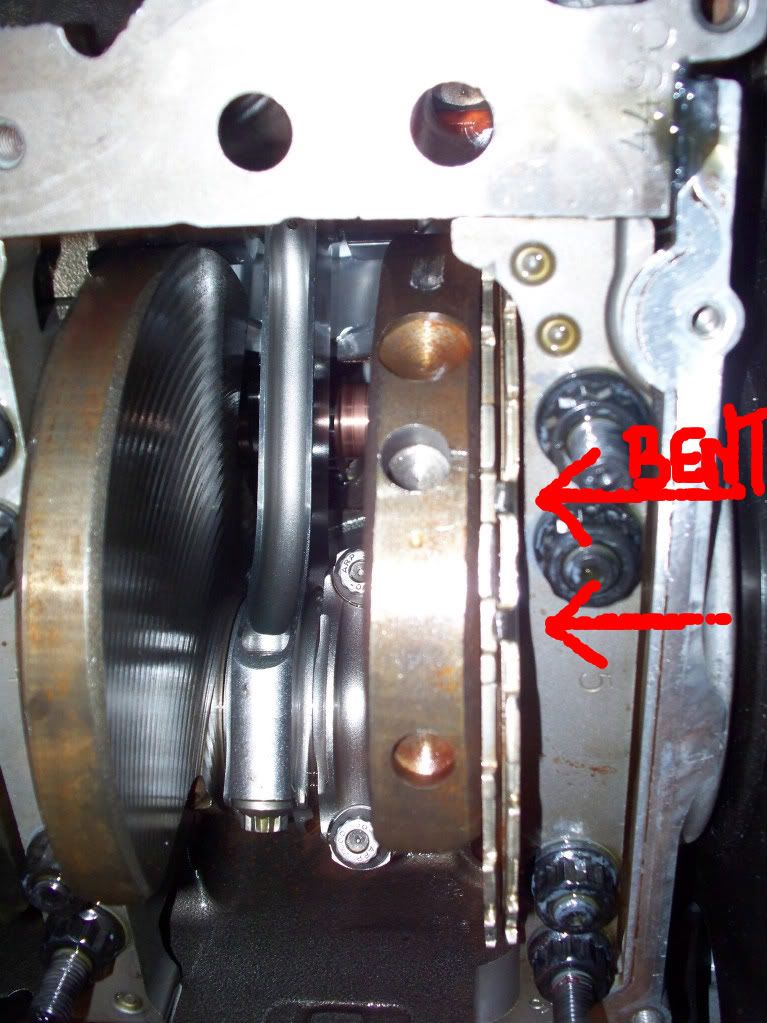

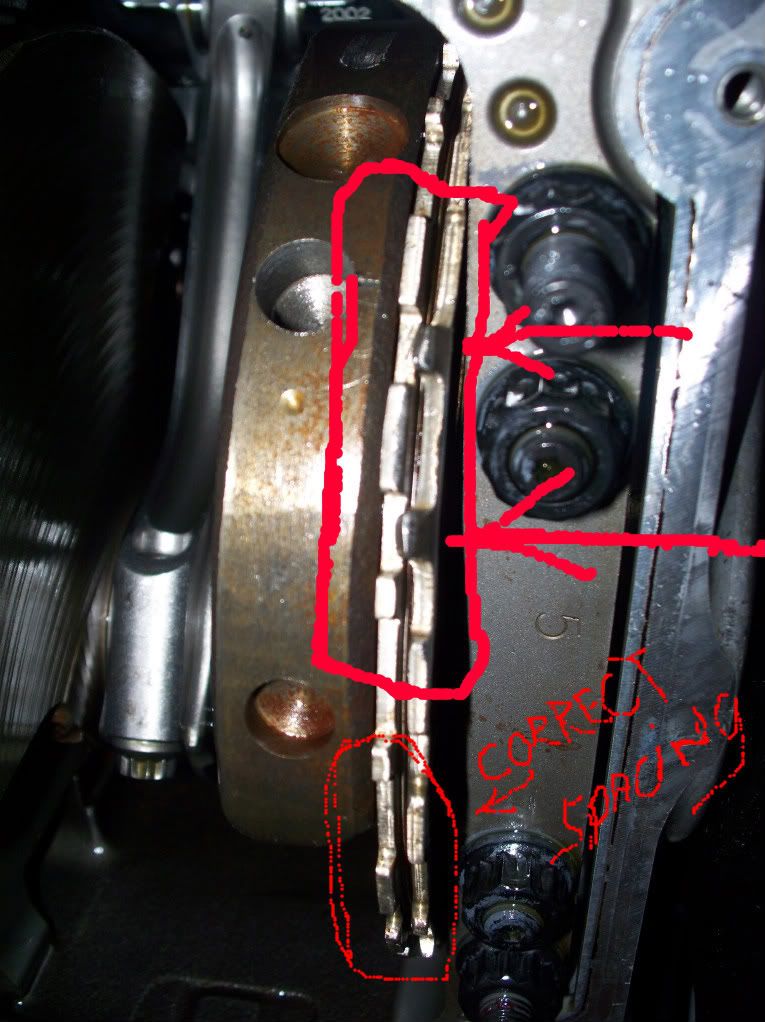

So I turned a the crank and used a mirror and looked thru the sensor hole and saw two places with the crank reluctor wheel tab was bent. In two spots the back row had two spots where they bent over into the space of the front row.

1 HOW TO FIX THIS?

IF I bent the tabs back in order will it work. Im trying to drop the k meber and pull the pan i just unbolted the motor mounts. any help would be greatly appericated.

Reply With Quote

Reply With Quote . 11.87 @ 114

. 11.87 @ 114

hard to tell from the angle but the tab were completly bent over. Im just worried about the spacing between the two reluctors

hard to tell from the angle but the tab were completly bent over. Im just worried about the spacing between the two reluctors